google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

Homogeneous thin films of functional nanomaterials -- Nano-spraying -- YMUS ultrasonic spraying

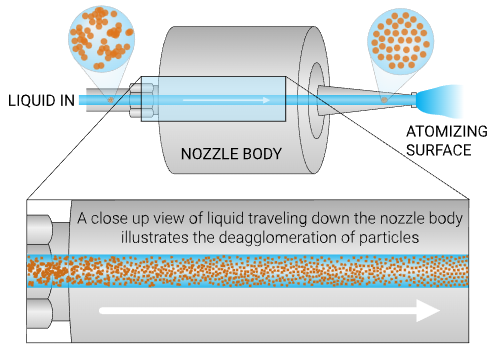

YMUS ultrasonic nanomaterial coating system is particularly suitable for spraying carbon nanotubes, nanowires, perovskite, graphene and other nanosuspensions. Due to the ultrasonic vibration inherent in the nozzle, the energy separates the aggregated particles in the suspension, and the liquid is subjected to continuous mechanical vibration throughout the coating process without damaging the material. This is particularly beneficial when uniform dispersion of functional nanoparticles is required. In contrast, other spray techniques do not disperse clumps and are prone to clogging.

Note:Ultrasonic atomizing nozzle

Nanomaterial coatings benefit from the use of ultrasonic spraying equipment to spray nanosuspensions in a variety of ways:

● The ability to spray ultra-thin conductive layer with required electrical and transparent characteristics;

● Nanoparticles are evenly distributed on the substrate to maximize the use of materials;

● Targeted low speed spraying leads to very little overspraying of expensive materials;

● Ultrasonic coating systems offer greater flexibility, control and cost effectiveness than other deposition methods such as dipping, rotation and traditional spraying.

● Droplet size selection, the lowest up to 13 microns, depending on the nozzle frequency used;

● The programmable XYZ coating system provides a complete solution for your coating process, from R&D laboratory scale to mass production manufacturing;

● Fine wire or large area nanometer coating;

Examples of commonly sprayed nanomaterial applications:

● Deposition of CNT (carbon nanotubes), nanowires, perovskite materials, graphene in a uniform thin coating for alternative energy, electronics, semiconductor or medical applications;

● Fuel cell manufacturing in the spray of carbon black, platinum solution and other catalyst ink;

● Protective and enhanced applications using graphene or carbon nanotubes;

● All kinds of nanomaterials for EMI shielding;

● Create a transparent conductive coating;

● Deposition of uniform nanowires or graphene films for advanced electronics applications;

The YMUS Ultrasonic coating system is used to deposit nanolayer coatings of uniform thickness on substrates of any width. Being able to create these very thin coatings with a high degree of uniformity, even over very wide widths, ultrasonic spraying technology is well suited for many precision nanotechnology spraying applications.