google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

Removal of nano-particle contaminants on wafer surface——High frequency megasound Cleaning machine——Shanghai Yangmi Megasound Cleaning Machine

Mega sound cleaning mechanism

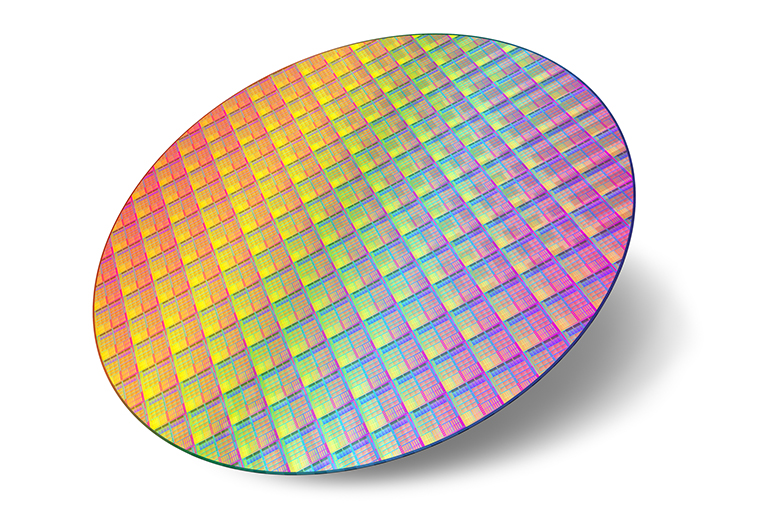

The mechanism of megatonic wave cleaning is that the silicon wafer is cleaned by the high energy frequency vibration effect combined with the chemical reaction of cleaning agent. In the cleaning process, the transducer sends out high-energy sound wave with the wavelength of megahertz, and the solution molecules accelerate their movement under the push of the sound wave. The maximum instantaneous speed can reach 30cm/s. Due to the high frequency, cavitation bubbles like ultrasonic cleaning cannot be formed, but only the high-speed hydrodynamics layer generated by strong sound pressure gradient and sound flow can continuously impact the surface of the substrate. The particles that attach the substrate surface are forced off and into the medium solution. Megatonic wave cleaning not only preserves the advantages of ultrasonic cleaning, but also overcomes its shortcomings.

Megatonic wave cleaning can remove particles less than 0.1llxm on the surface of the substrate, playing a role that ultrasonic can not play. This method can simultaneously play the role of mechanical cleaning (torsion) and chemical cleaning. In addition, mega acoustic wave cleaning frequency is higher, it is different from the ultrasonic cleaning of standing wave, will not damage the cleaning object. In addition, megatonic wave has more advantages than ultrasonic wave in viscous layer thickness, power density, resonance effect and diffraction effect.

Mega acoustic wave cleaning technology, as a representative of ultra-precision cleaning nanoscale cleaning technology, plays a pivotal role in the field of semiconductor cleaning. It has become a cutting-edge precision cleaning field, which can be used for ultra-precision cleaning of brittle materials such as wafers, semiconductor components, photomask and thin film magnetic head. At the same time, it can handle etching cleaning, bonding cleaning and other advanced packaging areas of precision cleaning.

The most widely used wafer cleaning technology, Meg wave cleaning technology is regarded as a key method of semiconductor wafer cleaning, which helps to test the fresh activity of the wafer surface after CMP. The surface of the wafer absorbs nanoparticles and other pollutants, and it is very difficult to clean after CMP. Because ultrasonic cleaning is difficult to remove the particles less than 1 μm on the surface of semiconductor wafers, but the surface damage of megatonic wave cleaning is small, can effectively remove the particles less than 0.2μm on the surface of wafers, can achieve the role that ultrasonic can not play. At the same time, the frequency of the giant acoustic wave cleaning technology is too high, it is difficult to produce cavitation effect in the solution, no ultrasonic cleaning bubbles will be formed during cleaning. When the high-frequency acoustic wave energy accelerates the continuous impact of the solution on the surface of the silicon wafer, so that the particles on the surface of the silicon wafer are stripped together with the solution. In order to achieve high efficiency and high precision of wafers, mega strength cleaning technology has the function of both mechanical cleaning and chemical cleaning.

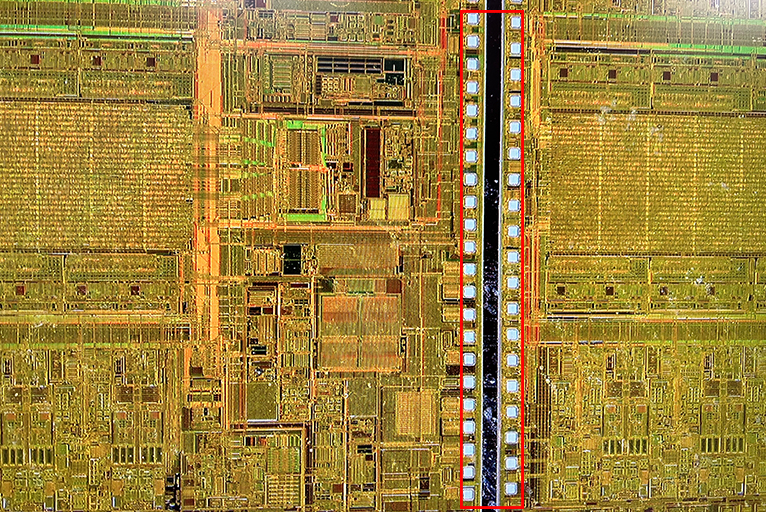

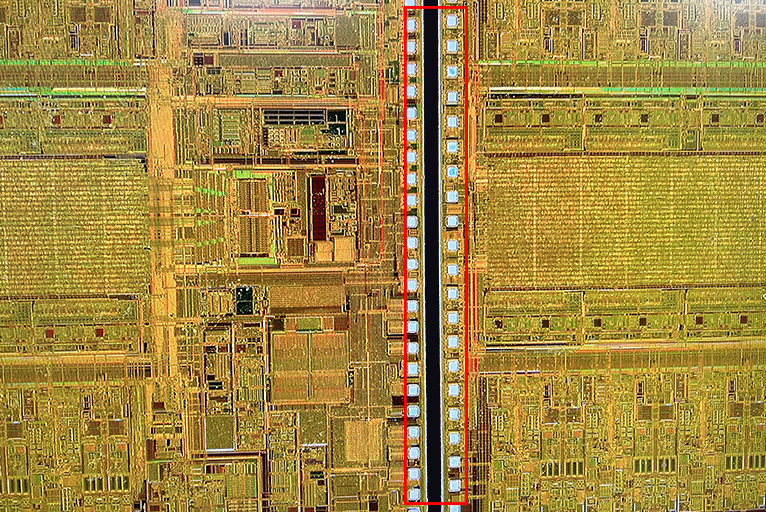

Before cleaning After cleaning

Megabound cleaning is usually divided into spray type megabound cleaning and trough type megabound cleaning. The spray type megasound cleaning is to transmit the high frequency ultrasonic wave through the water flow through the high frequency ultrasonic transducer, and the object to be cleaned contacts the water flow with the high frequency ultrasonic wave to achieve the purpose of cleaning treatment. Trough type megasound cleaning is similar to traditional ultrasonic cleaning. The high-frequency megasound cleaning oscillator is located at the bottom of the cleaning tank, forming the high-frequency ultrasonic sound field in the cleaning pool. The advantage of trough type megasound cleaning is that multiple wafers can be cleaned at the same time, which is more suitable for batch cleaning.

Product Features:

● Input power: 600-1200W

● Frequency: 1MHz

● Effective cleaning area: 135-160mm

● Megabound vibration plate, used to assemble the trough type megabound cleaning equipment

● 1MHz UHF megabound, more fine sound processing effect

● Uniform megabond sound field, vibration plate surface sound intensity can exceed 5W/cm2

● Advanced quartz and sapphire coupling technology, no risk of impurity shedding

● Low acoustic cavitation effect, no damage to the surface of the device

● High anticorrosion, can resist all kinds of acid and base solutions and organic solvents

● MEAE sound field evenly distributed, improve the cleaning uniformity

● Can be comprehensive non-metal high anticorrosive material, suitable for various acid base and organic solvents

● Unique transducer fitting technology, higher stability and durability

Shanghai Yangmi mega acoustic cleaning system has automatic trough cleaning equipment, high frequency mega acoustic cleaning machine, mega acoustic cleaning nozzle and so on. We will provide refined cleaning technology for effective application in your industry area.