google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

The preparation process of perovskite layer can be mainly divided into wet method (solution method), dry method (gas phase method) and gas phase deposition assisted method (dry-wet combination), and each route has its own advantages and disadvantages. The solution method can be divided into spin coating, coating, ultrasonic spraying and other methods. The solution method is simple to operate, has a fast film forming speed and low cost. Among them, ultrasonic spraying is an innovative method in the current industrialization.

Comparison of spraying processes:

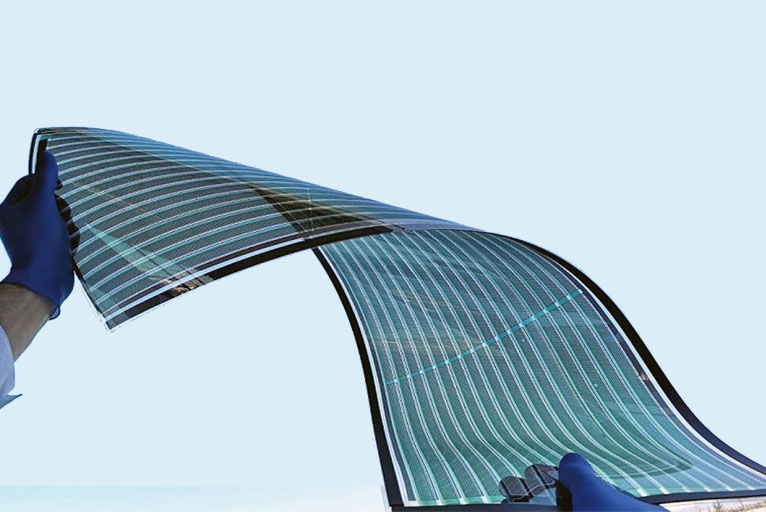

Ultrasonic spraying technology: Use high-frequency vibration to atomize the perovskite precursor solution into micron or nanometer-scale particles. By precisely controlling the parameters, the droplets are uniformly deposited on the substrate surface to form a high-crystallinity, low-defect film. When preparing on a large scale, by adjusting the nozzle parameters, uniform deposition of meter-sized films can be achieved, and uniform films can be formed on both rigid and flexible substrates.

Slit coating technology: The solution is made to flow out of the slit-shaped nozzle to form a thin film on the substrate through pressure. The slit width, die head moving speed, etc. can be finely controlled, and large-scale preparation and continuous production are possible. It may be affected by factors such as solution viscosity, coating speed, and substrate flatness. These parameters need to be precisely controlled to ensure uniformity.

Industry pain points:

1. The main problem of poor consistency in large-area coating when using the slit coating method to prepare perovskite is that it has a large area.

2. Large-area perovskite components have surface and internal defects and other undesirable problems, which affect the performance of the final product.

3. Pinholes, cracks and other defects will appear during film deposition and crystallization.

4. "Dead zones" will appear during laser scribing. The larger the dead zone, the smaller the effective power generation area.

Aiming at the pain points of the industry, Shanghai Yangmi has developed and produced perovskite coating solution related equipment: YMUS-CS1000 large area spraying equipment

Large-area ultrasonic precision spraying machine is a mass-production automatic ultrasonic spraying equipment, which can be equipped with wide-spray ultrasonic nozzles and can carry multiple nozzles to work in parallel at the same time. The automatic conveyor can automatically convey the samples, which is particularly suitable for mass-production and large-area thin film spraying. Such as fuel cell membrane electrode spraying, various glass coatings, thermal insulation film spraying, AR anti-reflection film spraying, photoresist spraying, transparent conductive film spraying, super hydrophobic coating spraying, etc.