google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

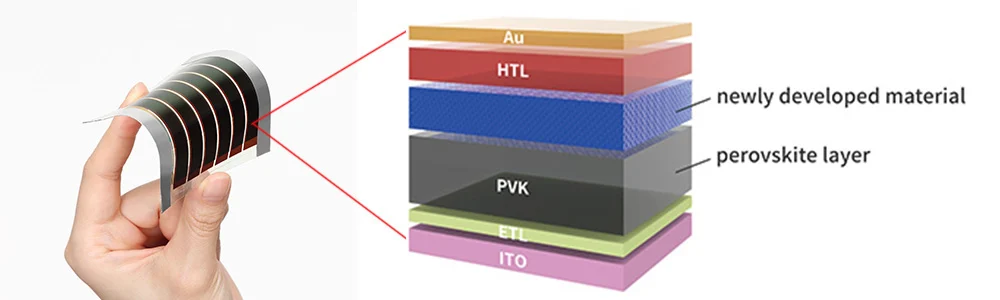

In the structure of perovskite solar cells, the hole/electron transport layer and the interface passivation layer have a key impact on the performance of the cell. In terms of the preparation of the hole/electron transport layer, ultrasonic spraying can accurately control the thickness of materials such as TCO (such as ITO), PEDOT:PSS, and metal oxides (such as NiOx). When it comes to the use of lead iodide solution to prepare related composite coatings, it can accurately cooperate with other materials to optimize the interface energy level matching. For example, when preparing a specific functional transport layer containing lead iodide, the lead iodide solution and other transport layer material solutions are sprayed on the substrate in proportion and accurately through ultrasonic spraying technology to form a uniform and appropriately thick composite transport layer to ensure the high efficiency of charge transfer. In the preparation of the interface passivation layer, ultra-thin two-dimensional perovskites or self-assembled monolayers (SAMs) can be deposited by atomization, and lead iodide, as an important component of the perovskite precursor, can be accurately involved in the construction of the ultra-thin two-dimensional perovskite passivation layer through ultrasonic spraying, reducing interface defects, greatly improving the charge extraction efficiency, and thus improving the performance of the entire perovskite solar cell.

Ultrasonic spraying technology also performs well in the preparation of crystalline silicon stacked cells and silicon heterojunction stacked cells. In crystalline silicon stacked cells, the traditional solution method has many limitations on the substrate, while ultrasonic spraying technology can break through these limitations and prepare a uniform perovskite layer. In this process, the lead iodide solution is evenly sprayed on the surface of the crystalline silicon cell and other specific locations through ultrasonic spraying equipment, participating in the formation of high-quality perovskite light-absorbing layers and other structures, achieving effective compounding between different battery structures, and improving the photoelectric conversion efficiency of stacked cells. For silicon heterojunction stacked cells, their preparation is more sensitive to temperature, and ultrasonic atomization can be completed at room temperature or low temperature (<150°C) to avoid problems such as thermal deformation of flexible substrates. When using lead iodide solution to prepare related coatings, ultrasonic spraying can accurately deposit the solution on the substrate in a low-temperature environment to form a coating that meets the requirements, adapting to the low-temperature preparation requirements of silicon heterojunction stacked cells, and promoting the development and application of such high-efficiency stacked cells.