google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

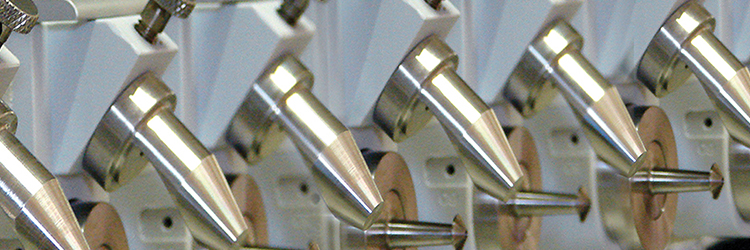

On-line spraying system, a mass production type automatic ultrasonic spraying equipment, can be equipped with a wide spray ultrasonic nozzle, and can be equipped with multiple nozzle parallel work. The in-line spraying system is also equipped with a unique precision constant-current metering pump system, which can achieve 24 hours of uninterrupted steady liquid supply. Optional carrier gas control, base heating, vacuum adsorption, exhaust system and other auxiliary devices, especially suitable for mass production and large area film production and preparation.

Ultrasonic spray machine

On-line spraying system

YMUS-ZX1000

* Suitable for wide area and mass production spraying

Online spraying:

float glass anti-corrosion spraying, medical, industrial, etc.Uniform spray width, repeatable film coating, spray width can be Adjust, stable performance.

On-line spraying system, a mass production type automatic ultrasonic spraying equipment, can Equipped with scattering ultrasonic nozzle, and can be equipped with multiple nozzle parallel workers Make it. The in-line spraying system is also equipped with a unique precision constant-current metering pump system,Can realize 24 hours uninterrupted steady liquid supply. Carrier gas control and base are optional Bottom heating,vacuum adsorption, exhaust system and other auxiliary devices, especially suitable for volume Production of grade and large area films.

Device Features

◆ Can be integrated to various fields of industrial assembly line installation;

◆ Can be matched with large width nozzle, uniform coverage of large area of substrate;

◆ Can be equipped with multiple nozzle array, greatly improve the production speed;

◆ Spraying uniformity: >95%;

◆ Solution conversion rate: ≥95%, 4 times traditional two-fluid spraying;

◆ Full color touch screen control and friendly man-machine interaction interface;

◆ A variety of high precision constant current liquid supply system to match different production capacity and different process needs;

◆ No clogging nozzle technology, low maintenance cost;

◆ Ultrasonic dispersed liquid storage barrel and ultrasonic dispersed syringe to avoid solid precipitation during spraying; (extensible)

◆ Liquid level alarm system;

Application

◆ New energy: fuel cell, membrane electrode, thin film solar cell, proton exchange membrane, etc;

◆ Medical treatment: balloon catheter, blood collection syringe, stent, biosensor, microfluidic chip, etc;

◆ Microelectronics semiconductor electronics: flux, photoresist coating, conductive coating, hydrophilic and hydrophobic coating, etc;

◆ Glass production: glass coating, float glass, photovoltaic glass, photoresistance film, transparent conductive, etc;

◆ Nanotechnology: carbon nanotube, polymer fiber, nano-film, etc;

Ultrasonic spray machine

On-line spraying system

YMUS-ZX1000

* Suitable for wide area and mass production spraying

Online spraying:

float glass anti-corrosion spraying, medical, industrial, etc.Uniform spray width, repeatable film coating, spray width can be Adjust, stable performance.

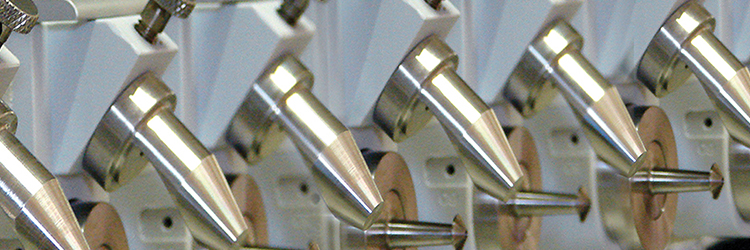

On-line spraying system, a mass production type automatic ultrasonic spraying equipment, can Equipped with scattering ultrasonic nozzle, and can be equipped with multiple nozzle parallel workers Make it. The in-line spraying system is also equipped with a unique precision constant-current metering pump system,Can realize 24 hours uninterrupted steady liquid supply. Carrier gas control and base are optional Bottom heating,vacuum adsorption, exhaust system and other auxiliary devices, especially suitable for volume Production of grade and large area films.

Device Features

◆ Can be integrated to various fields of industrial assembly line installation;

◆ Can be matched with large width nozzle, uniform coverage of large area of substrate;

◆ Can be equipped with multiple nozzle array, greatly improve the production speed;

◆ Spraying uniformity: >95%;

◆ Solution conversion rate: ≥95%, 4 times traditional two-fluid spraying;

◆ Full color touch screen control and friendly man-machine interaction interface;

◆ A variety of high precision constant current liquid supply system to match different production capacity and different process needs;

◆ No clogging nozzle technology, low maintenance cost;

◆ Ultrasonic dispersed liquid storage barrel and ultrasonic dispersed syringe to avoid solid precipitation during spraying; (extensible)

◆ Liquid level alarm system;

Application

◆ New energy: fuel cell, membrane electrode, thin film solar cell, proton exchange membrane, etc;

◆ Medical treatment: balloon catheter, blood collection syringe, stent, biosensor, microfluidic chip, etc;

◆ Microelectronics semiconductor electronics: flux, photoresist coating, conductive coating, hydrophilic and hydrophobic coating, etc;

◆ Glass production: glass coating, float glass, photovoltaic glass, photoresistance film, transparent conductive, etc;

◆ Nanotechnology: carbon nanotube, polymer fiber, nano-film, etc;