google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

The importance of cleaning process

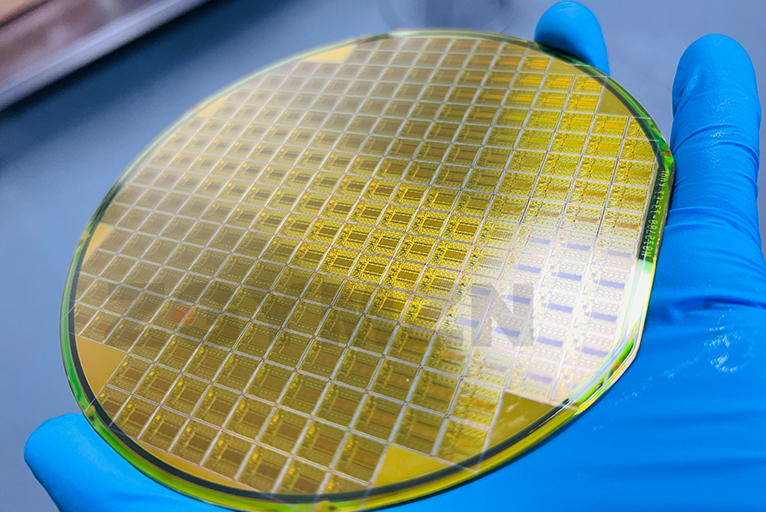

With the development of large scale integrated circuit, the importance of wafer cleaning is more and more prominent, and the requirement of precision is also more and more high. When the process node is 35nm, the parameter requirements are already very high, and the particle density and COP on the silicon wafer surface should be less than 0.1 / cm2. Current advanced process nodes are below 5nm, which requires higher wafer cleaning parameters.

In wafer processing of each link, the cleaning process is indispensable, it is mainly used for removal of wafer processing upper-middle-class legacy of ultrafine particle pollution, metal residues, organic residues, mask and photoresist residue, can also according to the need of silicon oxide film, the material such as silicon nitride thin film or metal to wet etching, the wafer surface conditions to prepare next procedure.

According to the different media, semiconductor cleaning technology is mainly divided into dry cleaning and mega wave cleaning two categories. At present, mega wave cleaning is the mainstream, accounting for more than 90% of the total cleaning steps. According to different process requirements, megatonic cleaning uses specific chemical liquid and deionized water to clean the wafer surface without damage to remove impurities in the wafer manufacturing process, usually with ultrasonic, heating, vacuum and other technical means. Dry cleaning is a cleaning technique that does not use chemical solvents and can be cleaned with relatively single contaminants.

China's semiconductor market is vast, cleaning equipment has a good development prospects. Shanghai Yangmi central meter mega sound wave cleaning equipment has automatic groove cleaning equipment, high frequency mega sound cleaning machine, mega sound cleaning nozzle, etc. We will provide refined cleaning technology for effective application in your industry area.