google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

Ultrasonic spraying technology is an innovative spraying technology with advantages such as uniform spraying, controllable coating thickness, and environmental friendliness. It is widely used in the field of medical devices, such as:

● Cardiovascular stents: Spraying drug coatings or bioactive coatings on the surface of cardiovascular stents is an important means to improve the performance of stents.

● Artificial joints: Artificial joint replacement surgery is an effective method for treating joint diseases, and the surface coating of joint prostheses has good bioactivity and lubricity to improve the biocompatibility and wear resistance of prostheses, which can reduce joint friction, increase the service life of joints, and reduce the occurrence of postoperative complications.

● Medical catheters: Medical catheters are widely used in the medical field, such as urinary catheters and vascular catheters. In order to reduce the friction resistance and infection risk of catheters in the body, lubricating coatings and antibacterial coatings need to be applied to the surface of catheters.

● Orthodontic devices: In the field of orthodontics, ultrasonic spraying technology can be used for the surface coating of braces. Spraying biocompatible polymer coatings can reduce the stimulation of braces to the oral mucosa and improve the comfort of patients wearing them.

● Surgical instruments: Some surgical instruments such as scalpels and scissors are coated with ultrasonic spraying technology to improve their corrosion resistance and surface hardness.

Drug-eluting balloon catheter is a medical device used for interventional treatment, and the drug coating on its surface plays a key role in the treatment effect.

Drugs

Currently, the drugs commonly used on drug-eluting balloon catheters are anti-proliferative drugs, such as paclitaxel, rapamycin, and their derivatives. These drugs can inhibit the proliferation and migration of vascular smooth muscle cells, thereby effectively preventing vascular restenosis.

Carriers

The function of the carrier is to carry the drug and control the release rate of the drug. Commonly used carrier materials include polymers, such as polylactic acid (PLA), polyglycolic acid (PGA) and its copolymers (PLGA). These polymers have good biocompatibility and degradability, and can gradually decompose and release drugs in the body. In addition, some liposomes, albumin, etc. can also be used as drug carriers.

Drug coating production method

Solution coating method: dissolve the drug and carrier material in an appropriate organic solvent to form a uniform solution. Then soak the balloon catheter in the solution and coat the solution evenly on the balloon surface. Then evaporate the solvent to form a coating of the drug and carrier on the balloon surface. This method is simple to operate, but the uniformity and thickness control of the coating may be relatively difficult.

Physical vapor deposition method: use physical processes to deposit the drug and carrier materials in gaseous form on the surface of the balloon catheter. For example, through vacuum evaporation or sputtering and other technologies, the atoms or molecules of the drug and carrier are condensed on the balloon surface to form a coating. This method can produce a coating with good uniformity and precisely controlled thickness, but the equipment is more complex and the cost is higher.

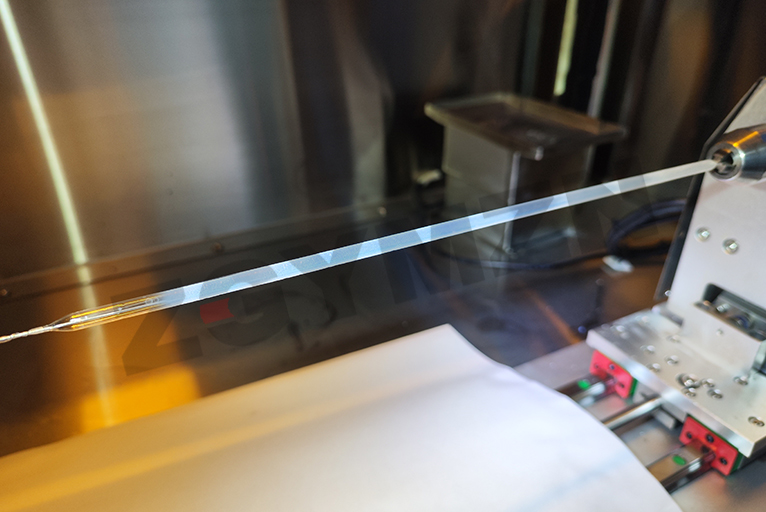

Ultrasonic spraying method: The high-frequency vibration of ultrasound is used to atomize the drug solution into tiny droplets, and then these droplets are evenly sprayed on the surface of the balloon catheter through a spraying device.

Advantages: Shanghai Yangmi ultrasonic spraying equipment can accurately control the thickness and uniformity of the coating, has high drug utilization, and can be sprayed at a lower temperature, avoiding the degradation of the drug at high temperature. At the same time, ultrasonic spraying can achieve uniform coating on the surface of objects with complex shapes, and is suitable for balloon catheters of various specifications and shapes.

First, the drug and carrier material are dissolved in a suitable solvent to prepare a spray solution with a certain concentration. Then the solution is placed in the liquid storage tank of the ultrasonic spraying equipment, and the solution is atomized and evenly sprayed on the surface of the balloon catheter by adjusting the parameters such as the frequency, power and spraying time of the ultrasound. During the spraying process, the balloon needs to be rotated and moved to ensure the uniformity of the coating on the entire balloon surface. After the spraying is completed, the solvent is removed by drying and other processes to solidify the drug coating on the balloon surface.