google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

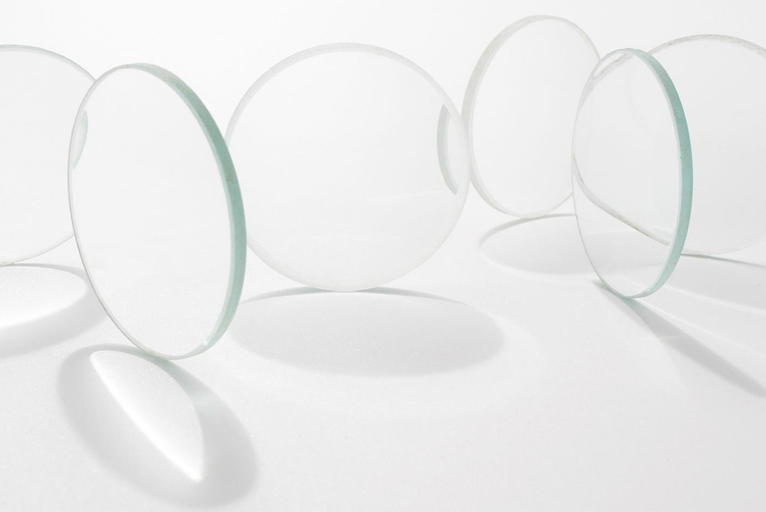

With the change of lifestyle and the popularization of technological products, people's requirements for eyeglasses are moving towards a new height of diversification and high quality. In daily work and study, facing electronic screens for a long time has prompted everyone to urgently need eyeglasses with excellent blue light protection function, effectively filter harmful blue light, and reduce eye fatigue and potential damage. When commuting or outdoor activities, the lenses should not only have excellent UV protection to block UV invasion, but also be able to quickly and accurately adjust the color under different lighting conditions, just like photochromic lenses, providing clear and comfortable visual experience. For consumers who pursue the ultimate light and thin experience, high refractive index lenses have become a favorite. While correcting vision, it greatly reduces the weight and thickness of the lenses, improves wearing comfort, and reduces the burden on the bridge of the nose and ears. In addition, the optical performance, wear resistance, anti-fouling effect of the lenses, and the adaptability to personal face shape and style are also included in people's considerations.

The following coatings are usually sprayed on the surface of eyeglass lenses and their functions:

● Anti-reflective coating: also called anti-reflective film, can reduce the reflected light on the lens surface, increase light transmittance, improve visual clarity, make the eyes more comfortable, and reduce lens reflections, making the appearance more beautiful.

● Anti-fouling coating: makes the lens surface have good anti-fouling performance, not easy to be contaminated with dust, grease and other stains, easy to clean, and keep the lens surface clean.

● Wear-resistant coating: enhances the hardness and wear resistance of the lens surface, prevents the lens from being scratched during daily use, and extends the service life of the lens.

● Anti-blue light coating: can effectively block some harmful blue light, reduce the damage of blue light to the eyes, and protect eye health.

Through ultrasonic spraying, these functional coatings can be evenly covered on the surface of the lens, improving the optical performance, wear resistance and easy cleaning of the lens, and providing consumers with a clearer, more comfortable and durable visual experience. Using the high precision and uniformity of ultrasonic spraying technology, we try to coat some nanomaterials with special functions on the surface of the lens, such as nano coatings with antibacterial and anti-fog functions, to expand the functions and application scenarios of eyeglass lenses.