google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

google-site-verification: google0228a1feb97d321e.html

Uniform dispersion of nanoparticles for conductive functional coatings -- Conductive Coatings -- YMUS Ultrasonic spraying

Conductive coating is a film or coating coated on the surface of insulating material with certain conductive ability. There are two main types of conductive coating: one is admixture type and the other is transparent film type. Admixture conductive coating is to mix fine particles of conductive materials into the filler of the coating, and brush or spray on the surface of insulating materials with organic or inorganic binder and thinner to form a conductive layer with certain conductive ability. It can be applied to rigid or flexible substrates by ultrasonic spraying process.

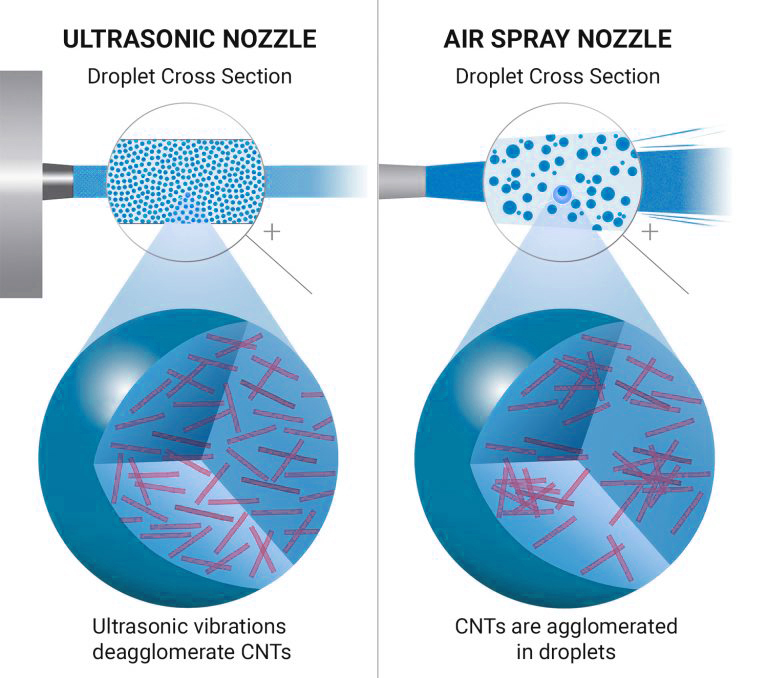

Ultrasonic spraying technology has obvious advantages in functional coatings such as transparent conductive oxide coatings. The ultrasonic atomizing nozzle is suitable for spraying the suspension with conductive particles and dispersing them evenly in the suspension to produce excellent electrical conductivity.

YMUS Ultrasonic Spray system is used to spray a variety of functional coatings on glass, plastics and metals of different sizes for many different applications:

● Transparent Conductive Oxide coatings

● Photoresist coatings

● Electrochromic coatings

● CNT or Nanowire coatings

● Anti-reflection (TiO2, SiO2) coatings

Evenly dispersed particles produce a larger active surface area, and thinner coatings create better electrical conductivity. The highly controlled spraying can realize the selective area spraying process that other spraying methods cannot achieve.